|

Automatic Welding Systems

|

|

www.Dorn-Robot.de

|

Welcome to our new Development

-this page has been optimized for mobile devices, simply scroll

|

|

|

-S (Surfacing) -S (Surfacing)

With drive unit RD500-B.

Internal Battery for 8 hours independent

wireless work, battery-charger plug and

Torch ON/OFF contacts.

|

|

|

Internal TFT-Touch-Display

for General Functions & Information

- Wire Feed-In, Start/Stop Weld

- Manual Positioning & Adjustment

- Drive to selected- or Zero-Point

- Load/Save parameter from/to SD-Card

- Power, Wire, Connection, Error -Info

|

|

|

Input-Screen

View & Adjustment of Parameters

- Integrated SD-Card Explorer

- Integrated Help-System to view

Speeds, Times, Distances in

mm/min, Seconds, mm

- Support for Chip-Cards

- Support for Arc-Control

- Full Functionality

|

|

|

|

close

Technical Data

Power Supply:

Internal LIPO Battery, 12 VDC/15Ah for approximately 8 hours of independent work.

Battery Charger : 12 VDC/1A , view

smartRobot-LIPO-Battery-Information.pdf

Option : External prim. 100-240 VAC, sec. 12 VDC/ 72W,

Or : External prim. 42 VAC, sec. 12 VDC/ 72W

Motors XYZ : DC-Motors,

12V/36W, 0 - 2200 mm/min, optional rotary support R: 60

RPM

Motor

Controls XYZR : Linear regulated, with computer controlled fuse and speed

adjustment.

Mechanical

Parts : Ball- and Linear-Bearings, 12 mm hardened steel rails,

warm gears and helical racks.

Turn

able torch holder, mounting knob for drive unit.

Mounting directly at work piece with clamps, magnets or screw able with screws M6.

Computer : 32-Bit

dual core micro controller, multiple interfaces, USB, Serial, I²C, CAN …

100% Quality-Management-System. Future

Operating System Update by WiFi or USB-Connection. Internal Flash memory and support for external user Chip-Card.

TFT Touch-Display : 2.4 inch bright display, 320*240 pixel

resistive touch-screen, integrated SD-Card.

Remote Pendant : Quad-Core 64-Bit phone, 5.1 inch HD bright display, spatter

protection foil, rubber cover.

Connections : Contact to power source, wireless WiFi, Bluetooth and/or USB interface to PC.

Amplitude : 0 - 120 mm; Oscillation Frequency

at 0.1 mm amplitude : 25 Hz max.

Movement : Weaver

X: 400 mm, Up/Down Z:

200 mm, Drive Y: 1300 mm, Rotary R:

endless

Encoder Resolution : 0.1 mm, Rotary R:

0.1 °

Dimension Unit (without rails) : 350 mm * 180

mm * 230 mm

Weight Welding

Unit : Approximately 14 Kg

close

|

|

First

Use

|

Installation of smartRobot.apk

Remote-Application on any Android Device

close

|

Installation of smartRobot.apk

Remote-Application on any Android Device

- Download Zip-Folder https://www.dorn-robot.de/Dorn_Robot.zip (12.4 MB)

and unzip.

The result should be a folder named smartRobot, including the file smartRobot.apk,

folder Info, folder Workspace

- Transfer the complete folder smartRobot via USB to your device

to folder: /storage/sdcard0/.

- Make sure that installation from unknown sources is allowed (Security, Unknown sources).

- With your File-Manager, select and click smartRobot.apk, follow instructions and wait for installation.

- You will find the application button together with your other app-buttons, - select to start App.

|

|

Active Connection

Time, Battery Charge, Serial Number

|

Switch Display Mode

Parameter View or Graphic View

|

|

Small embedded Graphic View

|

Switch Keyboard Mode

Move unit or Input parameters

|

STOP and 2nd Key-Functions

Double-click to switch ON 2nd function

for single touch handling

|

|

|

If your device has a menu button […], double-click to switch Keyboard size.

|

Pairing of Android Phone/Tablet and smartRobot-200/500 Welding Device.

- Switch ON both ON/OFF switches at welding unit, –the blue LED

will blink.

- Use internal Bluetooth-Software for pairing,

or select menu-button  to open menu connect. to open menu connect.

|

|

|

|

Select [Scan for devices] |

...select [smartRobotXXXX] |

...use XXXX as PIN |

|

(Pairing PIN XXXX = Serial Number)

If connection is completed, internal clock is running and serial number is indicated.

|

close

Download smartRobot.apk (1.1 MB)

Main Application Menu

Most of the functions are self-explaining, keyboard and display will show possible modes and actions.

Main functions are collected in the Main Menu at top of Application.

…simply touch to activate

|

|

|

File Explorer with all functions to create, copy, paste… files and

folders

|

|

|

Open Main Explorer Menu

|

|

|

Back to Main Application Display

|

|

|

Open and show storage directory

|

|

|

Open Transfer Data Menu or create QM-Document

|

|

|

Open Camera Menu for documentation by photo or video

|

|

|

Internal Camera, create/send picture or video…

|

|

|

External WiFi Live Camera, view frames…

|

|

|

External IR Live Camera, view thermographical frames…

|

|

|

Wireless connect to, or disconnect from, smartRobot welding unit.

|

|

|

Additional Menu, load default parameters, copy, Self-Test, About, Exit…

|

Standard Welding Functions

close

Standard Welding Functions

Welding Patterns Patterns can be adjusted in Input-Mode  by key by key

|

|

For V-shape and corner seams

For standard surfacing

Left or right side welding, along the input

line, with computer controlled adjustment.

Multiple Area welding with different parameters. For every area, a

different program can be used.

For repeated works, all Teach-In-Points are memorized with separate

programs (P 0-20).

For deep Wear Out

W

i t h

c h a n g i n g w e a v e r d i s t a n c e s f r o m layer to layer.

For Hard Facing with fast oscillating layers

With different dwell times for best

overlapping and vibration for fixing layers.

Multiple Areas can be filled automatically. To get a cold work

piece, for every area,

a special Count Down Timer is used (0-10 Minutes).

|

|

close

Welding Methods

Special welding patterns are available for all seam forms and applications.

All parameters are saved in up to 20 separate programs and the adaptation

of different circumstances is made easier. Recurring works simply occur

with quite tested, optimum settings.

... at Steel- / Ship- Construction |

|

V-shape Seam with Pattern 3  or 5 or 5

|

|

All welding parameters can be adjusted in steps by 1 %. The weaver amplitude should be as much as needed to reach both edges at least with half thickness of wire.

|

|

|

At V-shape seam with space, the torch should be mounted vertical or slightly backwards.

|

|

Corner  with Pattern 4 with Pattern 4  or 3 or 3

The torch should be mounted 45° angular and the corner shape will be worked out by synchronous movement of X and Z axes.

|

|

|

Surfacing with Pattern 1  or 2 or 2

|

|

|

The surfacing is comparable like with the welding methods at railway welds.

To get a better connection and overlap to the previous welded layer, the drive speed

at one side can be reduced.

The smartRobot welding unit works at up to 99 layers automatically.

|

|

|

Multi-Layer-Surfacing can be selected with mode Multi  and L01 up to L99 layers and L01 up to L99 layers

|

... for Cutting with Gas-Burner

close

|

|

... for Cutting with Gas-Burner

For cutting of any form of shape, up to

1200 Teach-In-Points can be used. Movement and positioning will be automatically calculated and interpolated between points.

Input of points can be done manually or external computed and transferred by USB or wireless.

3D-Cutter mode can be selected with key

|

close

|

For standard surfacing |

...for CMS hard facing |

...with multiple areas |

|

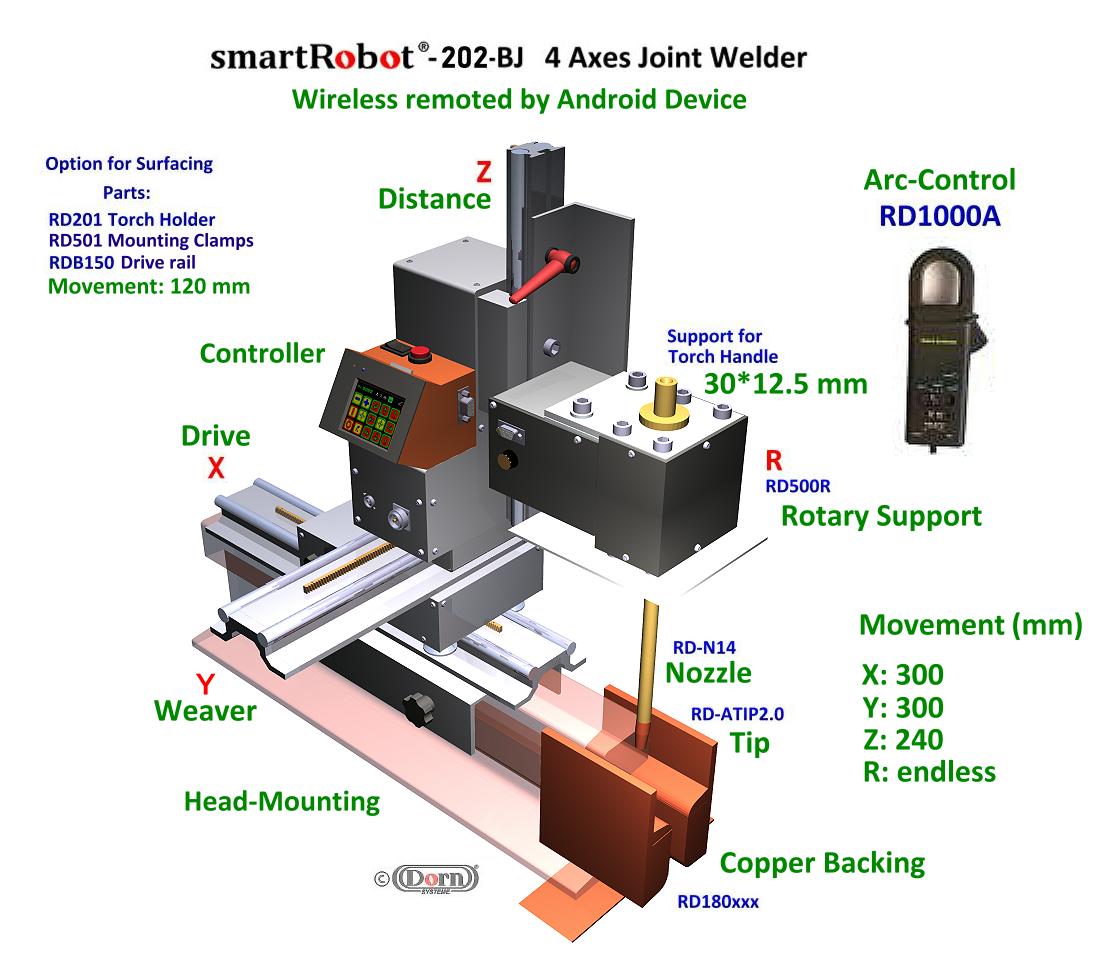

... Joint welding (Option)

with Rotary-Support and

4 axes movement

30 predefined rail types, easily select, expand or change.

|

Automatic welding sequences

|

|

|

Quality Management

Especially in the range of the welding technology, the quality assurance and quality

preservation is a responsible task. Therefore, the quality management doesn't end already

after delivery of the machines, but accompanies the whole period of use. Because of highest

technical standards and the logical use of all possibilities, the expenditure remains low.

For the optimum integration in quality management systems, certain circumstances have to

be fulfilled. Important points are the ability for reproduction of the processes, the data interchange

with documentation and the cost-use-factor of the quality management.

Because of the problems (provable, objectivity) of the different management models, special software for

computer-aided quality assurance is used.

Mainly integrated functions are the unit’s Self-Test, Encoder-Test and Camera functionality.

Self-Test

A predefined surface with predefined movement parameters, will be processed for 20 times

and the required time for every run is documented and saved. The maximum deviation should be only 1 second, if it's more than 2 seconds, Self-Test will be cancelled unsuccessfully.

This documentation picture will be created and automatically saved to QM-folder.

|

Just how the training and continuing education of the welder,

this test should be done regularly.

Self-Test can be selected in main menu  , Self Test , Self Test

Non-Contact Infrared Temperature Measurement and Documentation

For welding at big parts, preheat and/or interpass temperatures are very important and must be verified before start of weld. For easy and fast temperature information about the complete welding area, a thermographical camera is part of the welding system. Temperatures up to 300 °C can be detected and memorized for documentation.

|

|

Example of developer's coffee cup.

Hot spot marked with

Documentation can be selected with key

|

WiFi-Access-Point for real-time Data-Tracking

With WiFi functionality, a wireless Access-Point via WiFi will be supported.

Any other unit or network with WiFi capabilities can be connected and data or command can be received or transferred.

|

|

Connect Browser with http://192.168.4.1

Download Application smartRobot.apk to remote

View SD content and transfer files

Get continuous Parameter and Data

Upload data and files

Upload operating system and update

|

|

|